Written by Gouri Sasidharan

Content Specialist, Esko

Written by Gouri Sasidharan

Content Specialist, Esko

These days, you open your smartphone camera, point it at the QR code on your shampoo bottle or food carton, and suddenly it opens a portal — not to the Upside Down with Demogorgons lurking in your pantry (thankfully), but to a world of traceability data, sustainability claims, allergen warnings, recipes, batch details, brand stories, and everything in between.

And here’s the kicker: the QR smart packaging market is expected to hit $8.6 billion by 2026.

What started as a fun way to send people to a contest page (this writer was definitely scanning cereal boxes) or a feel-good sustainability story has now become a regulated gateway to product information in multiple markets. The EU demands digital product passports. China uses QR codes for authentication. India is digitizing food and pharma compliance through QR-linked declarations and traceability.

In other words, QR codes have quietly become one of the most regulated elements on your packaging.

The irony? While the code itself is tiny, the risk it carries is massive.

Once your packaging becomes a door to live online content, the compliance responsibility doesn’t end with printing. Your QR must remain accurate, updated, and reliable for as long as the product is in circulation — sometimes months, sometimes years. And this is exactly where brands slip.

So, before your team ends up chasing a surprise audit or a recall notice, let’s break down the mistakes most brands don’t realize they’re making…until it’s too late.

Imagine a parent scanning a QR code on a candy box for their child, expecting fun games, only to land on a promo page for a horror movie. This leads to utter disappointment and mistrust.

QR-linked packaging can unlock great experiences, but only when everything behind the code works perfectly. Here are the most common mistakes brands make, and why they happen so often.

Someone scans the QR code during artwork approval, “Yep, opens the right page”, and that’s it; the validation ends.

Except that the linked page isn’t fixed like packaging artwork. It can break. A developer can push a new site structure. Redirect rules can change. The marketing team might take down a campaign microsite without informing Legal. So, the QR hasn’t changed, but its destination has.

What was compliant at print can become a liability after launch. And the brand only finds out when a customer posts a “404 – Page Not Found” screenshot on social media.

Nutritional values, allergen listings, recycling instructions, promotional claims, sourcing transparency, and such are legally controlled in many markets. The minute they go online via a QR, they come under the same scrutiny as the printed pack.

But while packaging claims go through strict approvals, web pages are edited freely. The product team updates the claim, marketing adjusts the copy, and optimizations happen once in a while. Meanwhile, the product on the shelf still points to information that no longer aligns with what was signed off.

The result? Outdated or misleading content hidden behind a shiny QR code.

Standardization sounds efficient: one QR for every market.

But in reality? Not all markets allow the same claims, languages, or disclosure rules.

A consumer in France might be led to content meant for India, featuring non-EU compliant claims. A Canadian shopper might land on a page with missing bilingual requirements. Regulators call that a violation. And they’re right.

Global QR strategies need localized intelligence. Otherwise, the smartest label becomes the riskiest one.

Packaging artwork has version control, approvals, audits, and sign-offs.

The QR landing page? Often a last-minute web update with zero traceability.

When an auditor asks, “What exact information did consumers see when this batch shipped in January?” most teams don’t have a record. They’re left digging through emails and Slack threads praying someone saved a screenshot.

QR validation comes as a final gate. And by the time anyone notices an error, the packaging is already printed. Fixing it is expensive and stressful.

Then products go live, and everyone assumes the QR will stay perfect forever.

Spoiler: it won’t.

The digital world and regulations move while humans edit things. So, you need to frequently validate these risks.

After looking at the biggest QR-related mistakes, one question remains:

Why are brands still running into these problems over and over again?

It’s simple: because they’re trying to manage a dynamic digital experience with a static quality-control process.

While printed packaging is like a frozen asset, the web content continues to change quietly.

When you add multiple SKUs, markets, claim rules, and stakeholders, keeping track of everything manually is impossible.

Here are a few examples of leading brands that show how QR codes can improve packaging when executed with purpose and consumer experience in mind.

As part of the global relaunch of their iconic Share a Coke campaign, Coca-Cola added QR codes to bottles and cans that take consumers to a Share a Coke digital hub where they can personalize packaging, create and share videos with friends, and engage with interactive “Memory Maker” experiences online. This approach blends physical packaging with a tailored digital experience that meets Gen Z’s appetite for authenticity and connection, turning a simple scan into a fun, personalized engagement.

Hershey’s was an early adopter of smart packaging, adding QR codes to packaging so consumers could scan and access comprehensive product information from detailed ingredients and nutrition facts to allergen definitions and product usage information. Hershey’s commitment to putting QR codes on hundreds of products demonstrated how packaging can extend far beyond what physical space allows, giving shoppers the transparency they increasingly expect.

M&S used QR codes on toilet roll packaging to link customers directly to a charity website with information about bowel cancer symptoms and support resources, as part of a public awareness campaign. Here, the QR served information that couldn’t fit on the pack and turned everyday packaging into a medium for health education.

For Pride Month, Skittles added QR codes to limited-edition bags that activated an immersive AR experience celebrating LGBTQ+ artists. Scanning the code didn’t just lead to a webpage — it unlocked a 3D artistic journey that helped connect product, community, and brand values in a way traditional packaging never could.

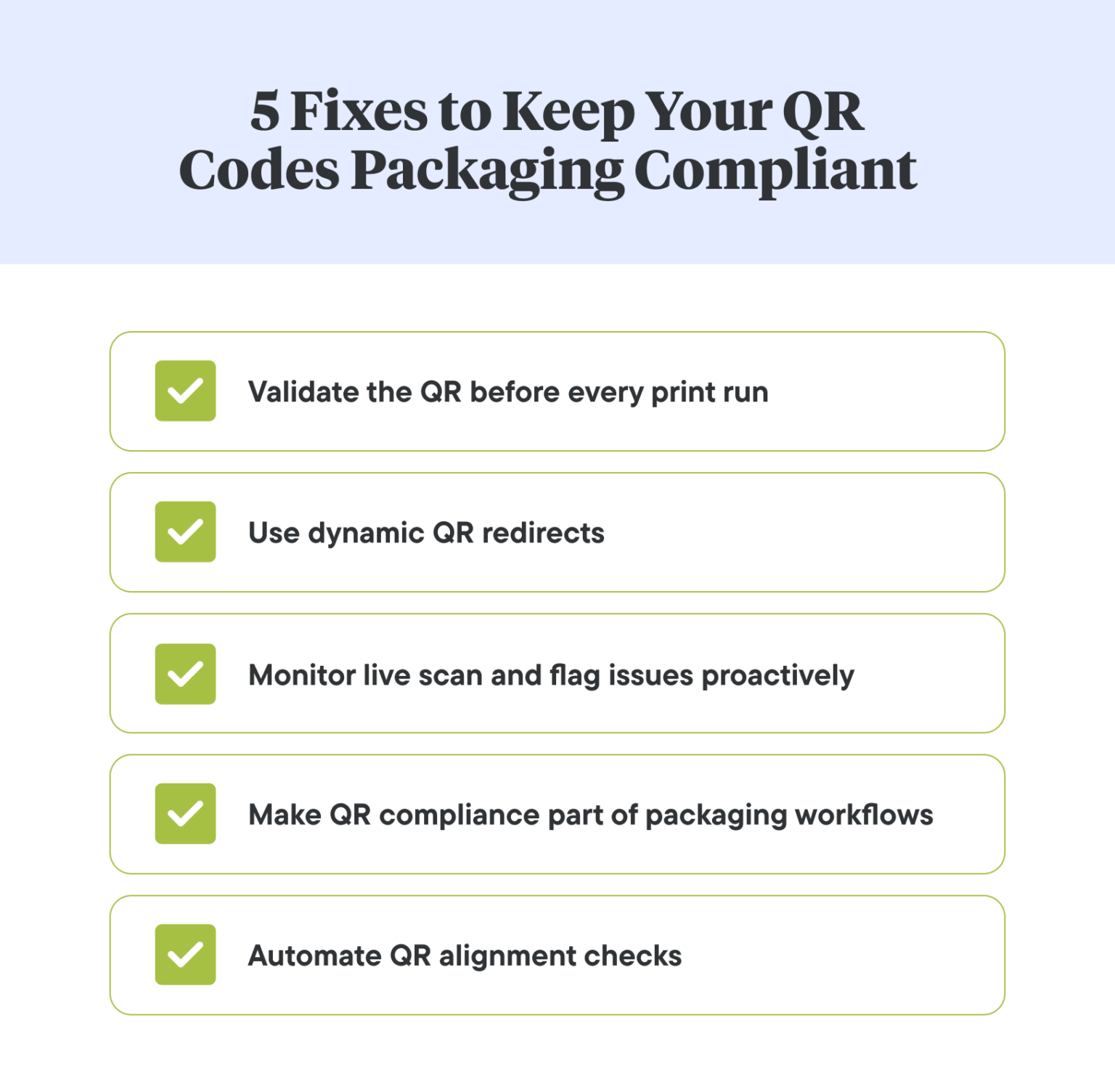

Your QR code is only as compliant as the journey it leads to. Here’s how your team can materially lower risk without slowing down launches:

A QR that scans flawlessly on-screen can fail once curved around a bottle or printed in low contrast. Always test final printed samples with multiple devices and scanning apps, especially in poor lighting and with slightly damaged packs. Real-world friction testing catches invisible risks early.

Dynamic URLs let you refresh claims, safety details, expiry info, or campaign pages without reprinting millions of labels. This also helps when regulations shift mid-cycle, and old content must be retired quickly.

Where there is a broken link, there is non-compliance (plus frustrated consumers). Schedule recurring checks for redirect integrity, page load failures, and device compatibility. Proactive monitoring prevents “surprise” compliance emergencies that only surface after launch.

Treat QR-linked content like any other regulated panel. If marketing or regulatory updates a destination page, that should trigger an auto label check. With Comply, not only can you run label reviews for claims and images but also barcodes and QR codes. Scroll down to learn more.

As portfolios grow, manual checks can’t keep up. Automation reduces human dependency and catches broken links, outdated claims, and misdirected QR journeys before they lead to recalls.

Every QR code must meet the same standards as any printed label element: scannability, correct encoding, reproducibility under print conditions, and compliance with packaging rules (barcodes, quiet-zone margins, contrast, etc.). Many recalls and compliance failures, especially in highly regulated sectors like food, pharma, or cosmetics, stem from QR/2D codes that fail to scan or link correctly.

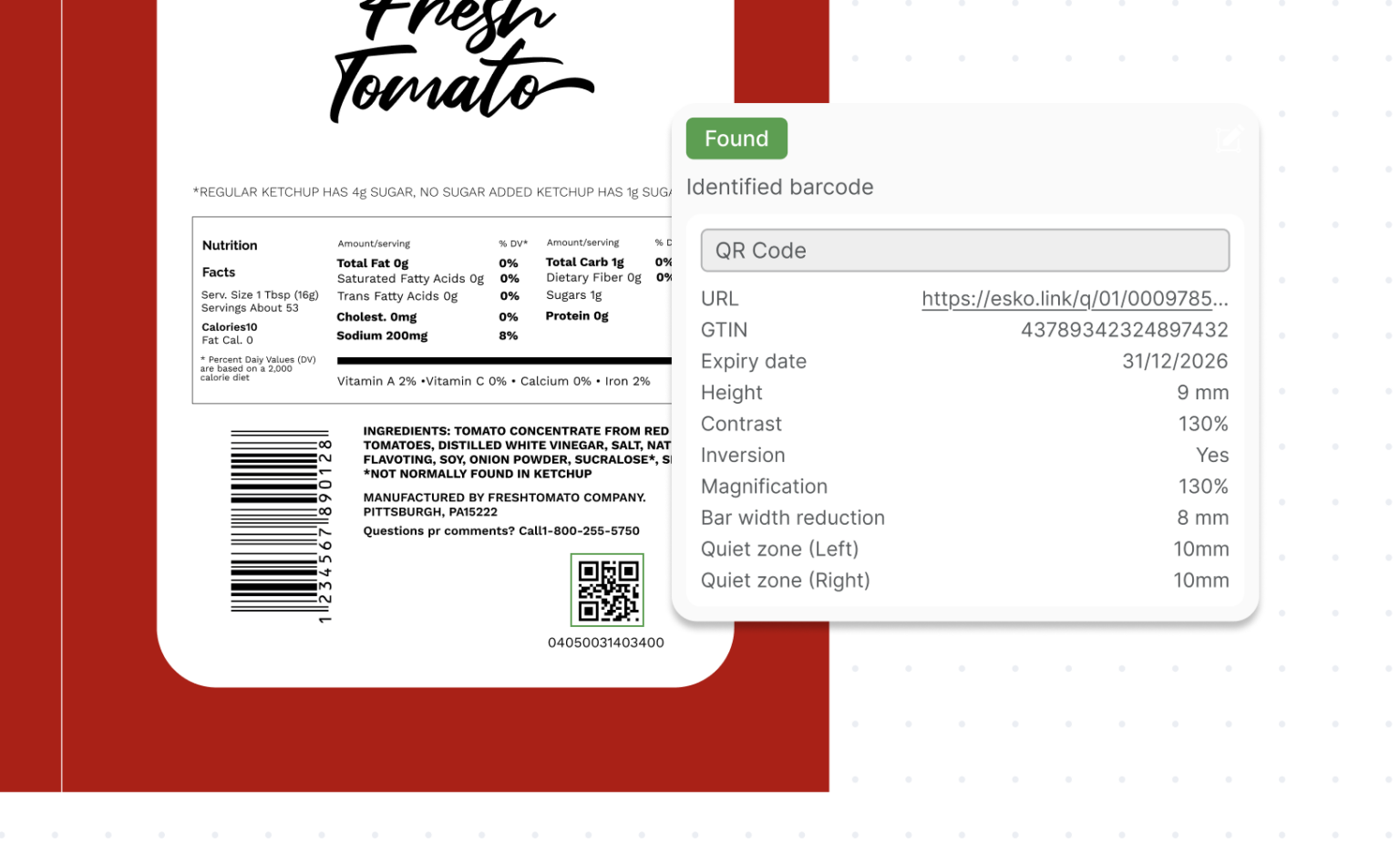

Here is where Comply comes. Our AI-powered label compliance tool provides a QR code validation feature. It analyzes whether the code meets technical requirements: adequate size and magnification, sufficient “quiet zone”, error correction, good contrast, and print-ready resolution.

This means you catch potential scanning failures before files even go to print, avoiding unreadable or broken QR codes, a common weak spot when QR codes are added without strict quality control.

QR code validation on Comply

And the best part is that Comply’s custom rulebooks and multi-market support ensure that QR codes and associated label content remain valid for each region. So, you don’t just validate that the QR code scans but also ensure that the right information behind the QR is compliant with local regulations.

QR codes let packaging do more than ever: connect, explain, and prove. But that connectivity is also a responsibility. A QR that fails to scan, routes to the wrong copy, or points to outdated claims turns convenience into a compliance problem.

If you want QR benefits without the risk, treat QR-linked content as a living part of your label lifecycle: validate it technically, govern it legally, route it correctly, and monitor it continuously.

Comply gives you reliability, control, and traceability rather than leaving QR codes for guesswork or manual review.

Book a demo to learn more and stay compliant.

Gouri, a content specialist at Esko, loves adding a dash of creativity to everything she writes. She dedicates her craft to creating and optimizing content for clarity and impact. On weekends, you can probably spot her exploring new cafés or at movies.